FAQ

Questions and answers about Hoppet and fossil-free constructions.

What kind of project is this? Just another preschool to be built?

Gothenburg City Council’s first task is to build a fossil-free preschool. The purpose is to highlight and push the issue and to inspire the industry to develop new fossil-free products and processes, but also promote and use the ones that already exist. It is a first step towards Gothenburg City, Sweden and the rest of the world's transformation into a fossil-free society without any climate impact.

To get the most out of the project, we must address it as an innovation program for fossil-free construction. In other words, we will stimulate, inspire and push more than necessary for preschool. We will highlight both existing fossil-free products and new ones that will be identified and developed during the project. In the future, this will affect all the demands we make when it comes to construction projects in the City of Gothenburg.

Why does the City of Gothenburg and its administration invest in this project?

Gothenburg is one of the world's most progressive cities when it comes to addressing our climate problems. In the City of Gothenburg, we should serve as a role model and show the world that it is possible to live a good life without contributing to negative climate impacts and by that changing the conditions for our future generations, both in Gothenburg and in the rest of the world.

This is very much emphasized in the Climate Strategic Program for the City of Gothenburg, a guiding document that specifies that the city will have a sustainable and rational greenhouse gas emissions level by year 2050. In order to implement the climate strategy program, the local administration received a task from the City Council to create a fossil-free preschool. This was in 2017.

The task is to consider all materials and products used in a building and during construction, as well as all stages of the process of transporting and manufacturing.

The aim is to minimize as much as possible, the climate impact in this project and show that it is possible. And not the least, to push and stimulate the industry to develop new fossil-free materials, methods and processes.

How much more will it cost to build a fossil-free preschool?

We don’t know yet. But we do know that research and expertise beyond the usual will be required. In addition to that, we will need to spend money on broadcasting the project, so we, amongst other things, can reach those who already offer fossil-free options and those who are ready to develop new ones.

We also want to reach out with the results and opportunities available within the program, so we can inspire more people to change the way they think. That is how we get the maximum value, according to the additional costs that can occur.

We do not know if it actually will cost more to build a fossil-free building. But we do think that it is reasonable to have a setup cost for the project.

Smaller batches are usually a bit more expensive than those who are bigger and benefit from a wider market. Certain materials will be more expensive due to changed content or manufacturing methods. We are also exploring the possibilities to reduce the amount of materials and products. In that case, it would benefit both the climate and the economy.

Our economical guideline is that the fossil-free products used in this project must have the possibilities to be cost effective when they are fully put on a wider market, making them a true alternative in future constructions.

The only thing we know for sure at this moment is that we will be totally transparent about costs and the amounts of greenhouse gas emissions.

Where will the fossil-free preschool be?

The plan is to build the pilot preschool on Backa kyrkogata 11, Gothenburg, on the southern part of the same site as the school Backaskolan. By the the year of 2030, our goal is that every preschool we build, will be as fossil-free as possible.

Are there any fossil-free buildings used as reference?

In the industrialized part of the world, we have not found any project that is fossil-free to the extent we are talking about (all products and materials, at all stages of the project).

But there are a lot of good examples, focusing on fossil-free materials with low climate impact, especially when it comes to framework, foundation and building envelope.

Other projects have focused on machineries and transportation. There are many interesting projects in Norway. On these pages, you will find information about them:

www.futurebuilt.no/Forbildeprosjekter

www.klimaoslo.no/2017/03/24/fossilfrie-byggeplasser/

We have also studied ”Det Biologiske Hus” in Middlefart, Denmark, a house that is said to biodegradable at the end of its life stage.

Which parts of a building or a construction process are not fossil-free today?

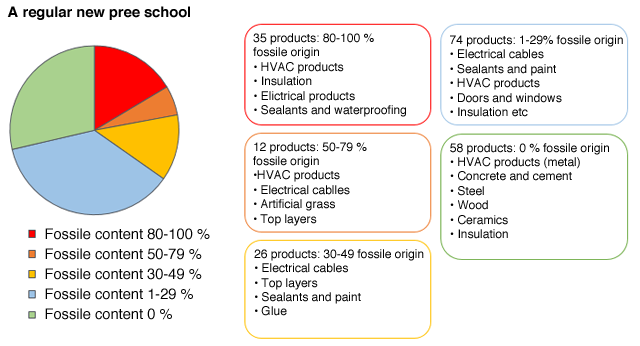

It is primarily the materials and products that contain fossil oil, like plastics, paints and adhesives. We have examined all parts of two relatively new preschools and have found almost 150 materials and products that are more or less based on fossil raw materials. The report will soon be available here. The result can be briefly summarized:

At the same time, we can note that the products containing fossil raw material account for only 10% of the construction's climate impact. The biggest part comes from the products found in the box with 0% fossil substances. This derives mainly from concrete, which has a climate impact due to cement production, where carbon dioxide is released during the calcination of limestone, but also from the large amount of heat energy required for this process. Steel production is another process that uses a lot of energy and therefor has a relatively large climate impact.

If the concrete is replaced with wood, the large amount of wood also contributes to climate impact, especially when choosing cross-laminated timber panels that need long-distance transports.

In the report series "Byggandets klimatpåverkan" you will find useful statistics on the climate impact that a building and the building process generally cause.

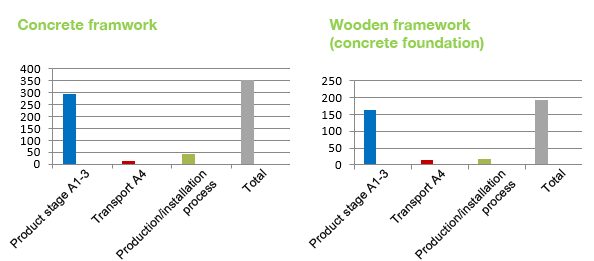

The largest part of the climate impact is from the manufacture of products (including transport to dealers). The transport to the construction site and the work at the site itself has a relatively small impact.

This is the starting point and we know that it’s already possible to reduce climate impact in all of these segments. However, to minimize climate impact, a lot of new methods, processes and materials are needed. And last but not least, fossil materials and fuels that have to be replaced by biomaterials and biofuels.

Who takes part in the pilot project?

The local administration of the City of Gothenburg is both project owner and developer. Bengt Dahlgren AB participates as an external project manager and LCA expert. The family owned wooden house manufacturer Derome is the main contractor.

What do you mean when you say fossil-free?

We mean that no fossil substances should have been used as a raw material in the products and the materials. Neither during extraction, transportations or in the machines. This also goes for the manufacturing industry or at the construction site where no fossil fuel sources should not have been used.

When we say fossil-free, we also mean a minimal climate impact. This means that we also include other emissions of greenhouse gases with climate-impact, such as carbon dioxide released when lime is converted to cement.

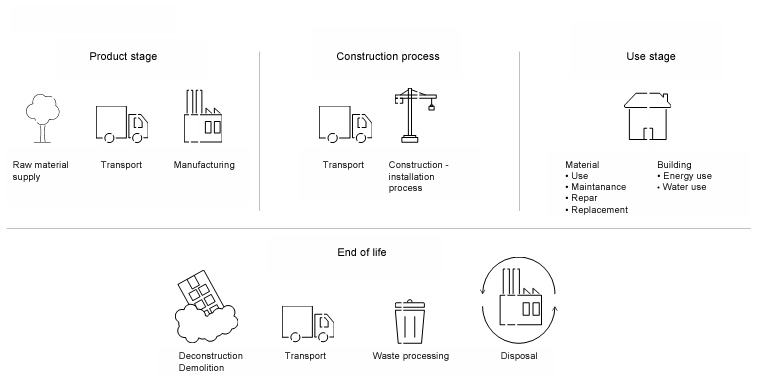

Which parts of the construction process are covered by the term fossil-free?

This project includes all steps, from exports through transport, manufacturing of material and product to the actual construction site. And also, the operation of the building once it’s built is included. We have chosen to focus on the steps that lead up to the construction site. We believe that it’s in those stages we can make the most important difference and contribute to the greatest development.

Which parts of a building are covered by the term fossil-free?

We look at all materials and products. Everything from building foundations and installations to paints and adhesives.

Will you prioritize when selecting products that just almost meet the requirement fossil-free? How?

In the beginning, we were considering whether we could create a general ranking method that we could use in all choices. But we realized that it would not favour the innovation and development in this project. Nor would it stimulate a change in attitude amongst people.

Instead, we want to decide on a case by case basis, product to product. For some product groups, the fossil content can be the most challenging to replace. And that’s when it is important to stimulate the development of a bio-based counterpart.

Today, a product may need to be transported a long distance or manufactured in an industry driven by fossil energy. We may not be able to change this during the course of the project, but we think that it’s fully possible in the future. Then we can stimulate the manufacturing of such a product, to demonstrate that it is possible. It can inspire others (who hopefully have more sustainable processes) to invest in similar products.

In other cases, the biggest problem is the long, fossil-driven transportation. If that’s the situation, this is where we will try to influence. The aim is to always choose products where all steps are fossil-free and have the lowest possible climate impact.

How do you handle conflicts of different requirements, e.g. environmental, functional or financial?

The starting point is that the solutions, systems, products and materials we choose should meet all our requirements. The local administration’s Technical Requirements and Instructions (TKA) can be found here.

The technical instructions exist to ensure for poison-free environments, energy efficiency, damp proofing, good indoor environment and the ability to efficiently manage and operate the properties. Should a fossil-free solution affect any of our other requirements, we will take that into consideration and determine which one weighs the heaviest to our cause.

What does LCA stand for?

LCA stands for life cycle analysis and is a method for assessing and presenting environmental impact. LCA aims to provide a comprehensive picture of how much the overall environmental impact is during a product's life cycle. From raw materials extraction, through manufacturing processes and waste disposal. Including all transportation and energy consumption in any intermediate steps. In other words, from the cradle to the grave.

Nowadays, we can also include circular flows, and that would be more like talking about cradle to cradle. When we say LCA in this project, we mean analysis of climate impact (greenhouse gas emissions).

Other environmental aspects are handled differently. For example, we use the Swedish system “Byggvarubedömningen” to assess chemical content and chose non-toxic building materials.

The lifecycle stages and modules we use complies with the European Standard EN 15978. See more under the question "Which parts of the construction process are covered by the term Fossil-free?".

When will the preschool be ready?

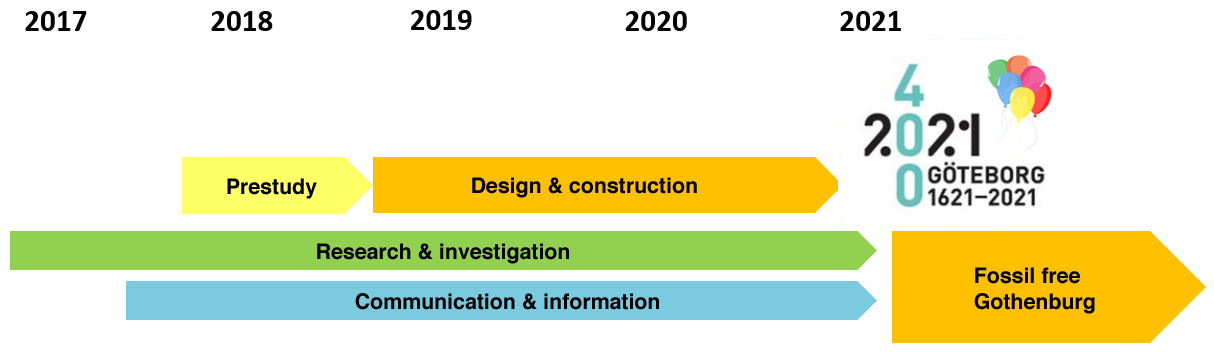

The planning, design and construction of the preschool took place in 2018 and 2019. And in December 2021 the preschool will be ready.

Will the innovation program continue when pilot preschool is ready?

The local administration and the City of Gothenburg's conversion into a fossil-free society will continue intensively for many years to come. So, this innovation program will continue. We are looking into what the next Hoppet project will be.

Is it reasonable to produce new products only for a preschool?

No, that's not reasonable. However, if our partners and suppliers develop a new and well-working fossil-free product, there will be lots of other construction projects where the product can be relevant.

Furthermore, the directions for all of the building companies and administrations is the City of Gothenburg are clear: everyone has to switch to fossil-free.

The development is the same throughout the whole country. And the market potential for good fossil-free products and materials is considered to be very high. We will highlight good initiatives and products to spread the cause.

How do we do if we have a product that we believe is suitable within the fossil-free building?

We are constantly looking for fossil-free products and solutions. Please send an e-mail to hoppet@stadsfast.goteborg.se.

What do you mean by partnering?

Partnering - or collaboration - is a structured form of cooperation where we as a contractor together with consultants, entrepreneurs, etc. solves the task. This model is based on a trustworthy collaboration, where everyone plays with an open hand and where everyone's professional skills complement each other through all the steps of the construction process. We gather the skills needed to implement and succeed with the project and that’s how we form the team.

We have an idea of a new or developed fossil-free product. How do we proceed of we want to develop it in collaboration with Hoppet?

We are constantly looking for new products and solutions. Please send an e-mail to hoppet@stadsfast.goteborg.se.

Who do we contact if we have questions about the Project?

Send us an e-mail at hoppet@stadsfast.goteborg.se, and the right person will contact you.

How do I stay updated and informed about the project?

Please follow us on Linkedin.